Metal Tags: The Difference Between Aluma-Tough & Stainless Steel

Metal Tags: The Difference Between Aluma-Tough & Stainless Steel

Both metal tags are extremely durable, and can withstand harsh environments, but understanding the differences between them can help you make the right choice for your application.

What is the difference between Industrial-Grade Aluma-Tough Sealed Anodized Aluminum & Stainless Steel Tags?

Stainless Steel Metal Tags

316 stainless steel contains molybdenum in it to help resist corrosion like sea salt water. So if you are specified to use stainless steel for your tag application and it needs to resist harsh chemicals, we suggest using the 316 stainless steel.

The stainless steel metal tags that NapTags offers come in .022”, .030”, and .050” thicknesses. These all can be laser cut and laser engraved to any custom shape and size. We are also able to laser engrave on 1/8” thick stainless steel.

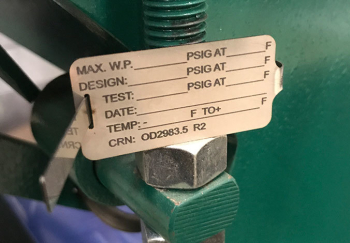

If you have specifications requiring you to use stainless steel, then this is a good route to go for ordering valve tags, asset tags, equipment tags, or any ID tag that is exposed to harsh environments. Nap Tags stainless steel tags are engraved with a laser that will not fade or deteriorate over time.

Aluma-Tough Sealed, Anodized Aluminum Tags

A lot of people think that stainless steel is the most durable material to use for metal tags, but Aluma-tough is actually more durable then stainless steel in many cases.

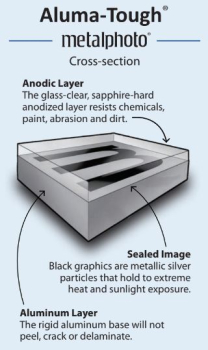

For over 50 years, industrial and military engineers have specified Metalphoto (AlumaTough) photosensitive anodized aluminum for durable nameplates, barcode labels, service schematics and control panels installed in harsh operating environments. Their proprietary technology permanently seals a UV-stable image inside of anodized aluminum, offering the confidence of unparalleled durability, image resolution and readability.

Aluma-tough is sealed with an anodizing solution, which creates a UV-stable image. It is impenetrable, deflecting chemicals, heat, abrasion, salt spray, and sunlight. It is certified for 20+ years in an outdoor application. This product has earned more top scores than any other barcode label material tested by the U.S. Navy. These metal tags meet a wide array of commercial, government, and military specs.

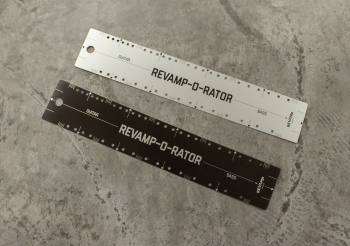

.020” – .063” Aluma-tough can be cnc-cut with beautiful clean edges. Thinner material is available as well. Thinner material is .012” thick (cannot be cnc cut) will have adhesive backing and is great for wrapping around curved surfaces. A lot of people use the thinner material for barcode labels because of the clarity of printing, capability to wrap around poles, and durability of the material.

Aluma-Tough material typically cost 10-20% less than stainless steel and is just as, if not more durable then the stainless steel. If you do not have specifications that strictly use stainless steel, then this is your best material to use.

Have questions on what industrial metal tag is best for your specific requirements?

NapTags has expert sales representatives that will guide you to find the best metal tag for your application. Feel free to email us at info@napsupply.com or call 1-800-451-3330.